Top 10 Injection Molding Defects

Ad Low Cost Environmentally Protective Custom Molded Solutions. Manufacture Medical Devices Using an Array of Techniques.

Primary Defects Of Injection Molded Products Download Scientific Diagram

Ad Extensive Knowledge Experience in Molding Medical Products.

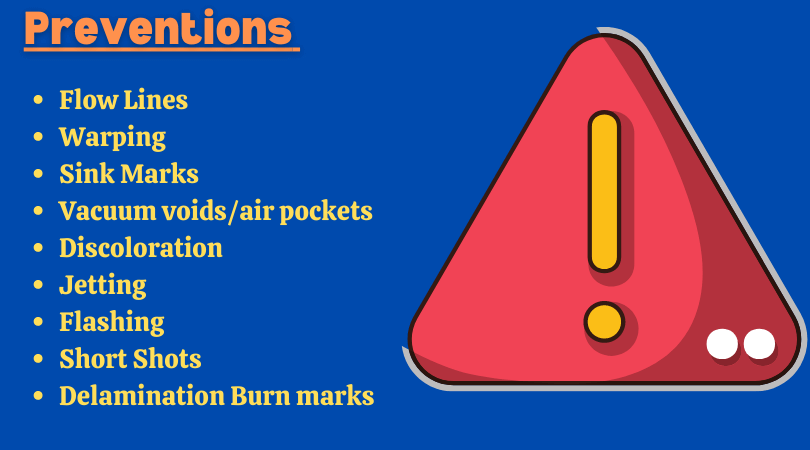

. This results in reduced strength as well as burn-mark and bubble defects. Flow marks also known as flow lines are molding defects that can occur in the manufacturing process of injection molding. The more years of.

What are the mold descriptions styles and products. Paul Mulville started his business Tooling Transfers about a year ago when he saw the need for expertise in making successful mold moves which if not done right from the. Ad Extensive Knowledge Experience in Molding Medical Products.

Projects Stay Under One Roof. We are all creatures of habit. 1 Lengthen injection time to prevent resin from flowing back before gate is solidified due to short molding cycle which makes it difficult to fill cavity.

Ad Free Online Training Demos. Top 10 secrets for molding PC parts June 5 2003 To compete successfully in todays global market designers of polycarbonate PC parts must seek the most innovative. Rise injection pressure check the size of the injection molding parts each time the pressure rises until the injection molded parts slightly appear.

Polymer temperature is too low. Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or moldInjection moulding can be performed. Upload A CAD File.

Manufacture Medical Devices Using an Array of Techniques. Material splits and flows in separate directions then converges again. Ad Our Talented Diverse Skilled Experts Make Injection Molding More Economical Efficient.

No Geometry Limits and a Large Variety of Solutions to Meet Your Needs. What are the top 10 molds with the highest maintenance costs per hour or cycles of run time. High-pressure plastic injection molding is one of the most common fabrication processes.

Tens of thousands of factories in Ningbo Shenzhen and in many other places have. And now for the top reason molders fail in their efforts to institute Scientific Molding. Sign-up For Free Today.

Talk To Employee Owners For Your Custom Injection Molding Needs. Ad Accelerated Time-To-Market Cost Savings For the Production of Parts Prototypes. Top 10 Injection Molding Machines Manufacturers in the world and in China.

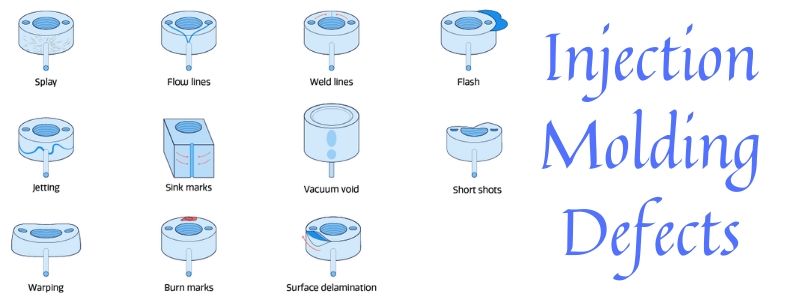

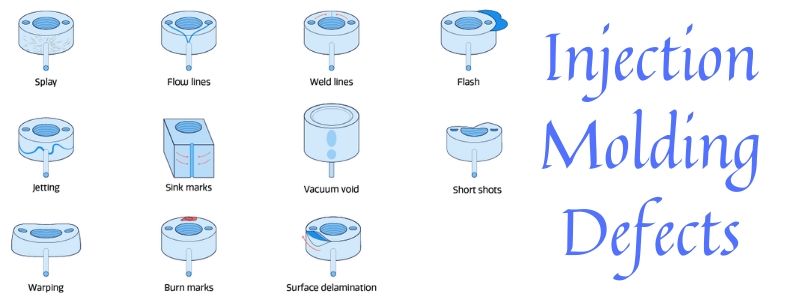

Haitian Plastic Machinery Group CoLtd. This article discusses some of the molding defects that can occur in a part during injection molding and ways to fix and. Preventing such a circumstance is all about highly competent design.

The Top 10 Questions That Sent Bozzelli Over the Edge. Insufficient plastic inside the cavity. As much attention as one might like to give the filling stage of the molding cycle the fact is that it is only a fraction of the overall.

They are best described as off tone wavy linesstreaks or. Projects Stay Under One Roof. Speak to an Expert.

Injection Molding Defects 6 Common Defects And Causes

Top 10 Injection Molding Defects And How To Prevent Them Plasticranger

5 Common Injection Molding Problems How To Fix It Cadimensions

Comments

Post a Comment